Composites

| Process overview | Fast RTM | |

| Fully automated RTM process | ✔ | |

| High Pressure Injection | ✔ | |

| Netshape | ✔ | |

| C-RTM | ✔ | |

| Thermoset resins (TS) | ✔ | |

| Thermoplastic resins (TP) | ✔ | |

| Production rate | Up to 30 parts/h | |

| Part dimensions | Up to 3m² | |

| On-line NDT | ✔ | |

| Process parameters monitoring and recording | ✔ | |

| Process simulation Numerical optimisation | ✔ |

C-RTM Process

With Compression Resin Transfer Molding process, the resin mixture is fed into the mold when it is slightly open allowing partial impregnation. Then a compression stroke presses the resin through the preform for complete impregnation. By this way an high-pressure resin injection allows the use of fast-curing systems.

Equipments

Eco Compact Sustainable Press (ECS PRESS)

|

|

|

|

|

RTM equipments and toolings

- Innovative modular toolings (net-shape, thermally optimized)

- Optimised temperature control system (current flow tube technology)

- TP and TS high pressure injection machines (30-250 cc/min)

|

|

|

|

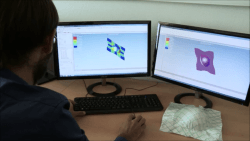

Automatisation

- Dedicated control room

- 6 axis robots (x2) – 700 kg capacity

- Modular prehensors (for preforms and composite parts)

|

|

|

Online monitoring, data saving and post-processing

- Online controls (preform and part)

- Centralised acquisition and archiving of process parameters

- Energy consumption measurement

Technical services

- Scale-up : Validate process/materials at an industrial scale

- Pre-industrialisation : Validate robustness and production rate of RTM/C-RTM processes in an industrial context

- Manufacturing cost reduction : Production cost reduction - Quantifiy economical advantages of RTM/C-RTM processes

- Materials developement : Maturation and industrilalization of new materials (résins or reinfocements)

- Process development : Optimisation of RTM/C-RTM processes and development of new processes

- Injection process optimisation : Development and/or optimisation of injection configuration (experimental and/or simulation)

Platform availability

- Multi-partner research projects with public co-funding

- Research studies/services for dedicated companies

- Platform rental with technical support

- Training